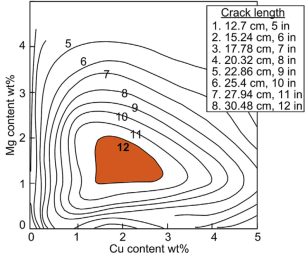

Hot Cracking Susceptibility Map of Al-Cu-Mg at Al-Corner

Purpose: In the Prediction of Hot Cracking Susceptibility of an Al-Cu-Mg Alloy, Users have learned how to obtain the crack susceptibility index (CSI) value of a single alloy under certain solidification conditions. In this example, users will learn to use High Throughput Calculation (HTC) calculations to obtain a susceptibility index map in Al-Cu-Mg ternary system.

Module: PanSolidification

Thermodynamic and Mobility Database: PanAl_TH+MB.pdb

Kinetic Parameters Database: Al_Alloys.sdb

Note: In Pandat™ 2022 version, the property CSI is defined as "-T//sqrt(fs)". In the "Table editor" window, users can directly select CSI or simply type in CSI rather than using the math operation of "-T//sqrt(fs)".

Calculation Procedures:

-

Create a workspace and select the PanSolidification module. Before calculation, save the workspace in a user assigned folder different from the default workspace. The HTC calculation results will be saved automatically under this folder. (Detailed description also in the Pandat User's Guide: Workspace;

-

Load PanAl_TH+MB.pdb through menu "Database → Load TDB or PDB" or by click icon

, and then select Al, Cu and Mg three components;

, and then select Al, Cu and Mg three components; -

Load SDB file Al_Alloys.sdb through menu "PanSolidification → Load SDB" or by click icon

, select the available alloys: Al alloys;

, select the available alloys: Al alloys; -

Start HTC function through menu "Batch Calc → High Throughput Calculation (HTC)";

-

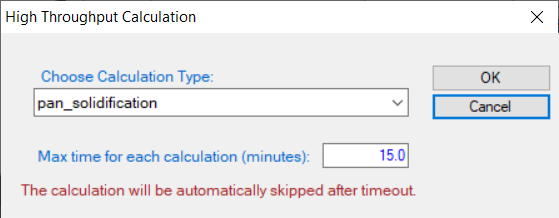

Choose calculation type from the drop-down list of HTC pop-up window and select “pan_solidification” as shown in Figure 1;

-

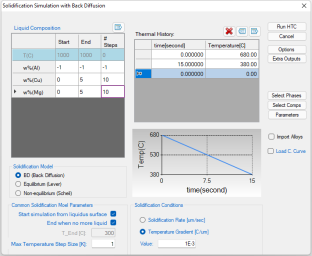

Define the compositional space for HTC simulation. The composition range is set to 0-5 wt.% Cu and 0-5 wt.% Mg, and mouse right click on the composition field of Al to set as the remaining composition, which is shown as -1 in all the composition field of Al, as shown in Figure 2.;

-

Define the solidification conditions for HTC simulation. The solidification conditions with cooling rate of 20 K/s and Temperature gradient is set as 10-3 °C/μm, as shown in Figure 2;

-

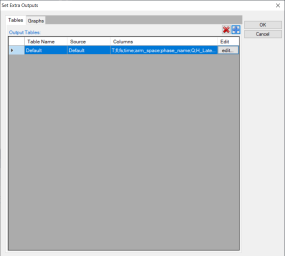

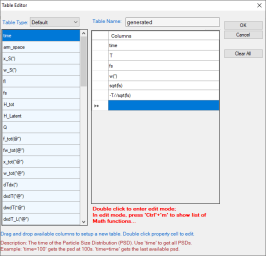

Set “Extra Outputs table”. Click the “Extra Outputs” in Figure 2, a new interface as shown in Figure 3 will appear. Click the blue “+” symbol in Figure 3 to pop out the Table Editor as shown in Figure 4. From this Table Editor, users can specify and type in properties to output, such as sqrt(fs), -T//sqrt(fs) in this example. -T//sqrt(fs) refers to -dT/d(fs)1/2, as the syntax // means derivative in Pandat™ software. Note that with this setting, a “generated” table will be created in addition to the Default table;

-

Set “Extra Outputs graph”. Using the procedure described in Example 5.2, click the icon “Graph” in “Set extra output”, set sqrt(fs) as X axis and -T//sqrt(fs) as Y axis. Then click OK;

-

Click “Run HTC” button to perform HTC simulations.(Detailed description also in Pandat User's Guide: HTC with PanSolidification ).

Figure 2: Dialog to setup compositional space and solidification conditions for PanSolidification HTC

Post Calculation Operation: Result Analysis

-

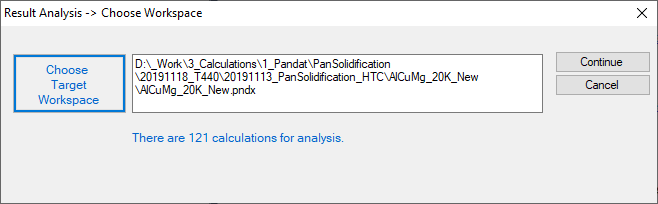

After all calculations have been finished, analyze the results through menu "Batch Calc → Result Analysis". User can then analyze the results of the selected HTC calculation by opening the corresponding workspace as shown in Figure 5.

-

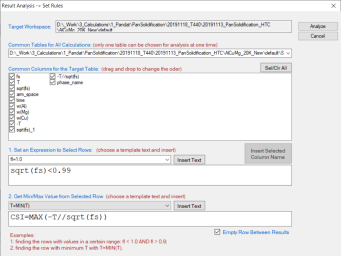

Define the criteria of the properties as filters for result analysis. As shown in the following Figure 6, analysis the “generated table”, set the condition to find the CSI for each alloy composition, i.e., CSI = MAX(-T//sqrt(fs)) at sqrt(fs)< 0.99;

-

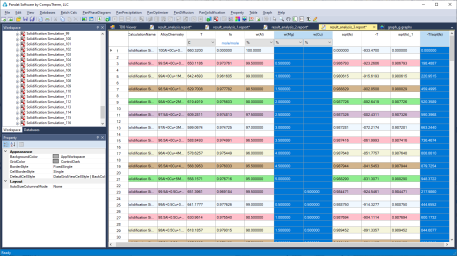

After results analysis, a table which list CSI = MAX(-T//sqrt(fs)) for each alloy composition is generated as shown in Figure 7;

-

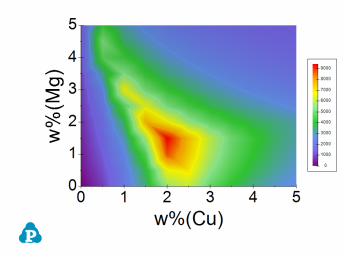

Select w%(Cu) as X-axis, press Ctrl then select w%(Mg) and (-T//sqrt(fs)) as Y-axis and Z-axis, respectively, click

on the tool bar to generate Figure 8 which shows the crack susceptibility map for Al-Cu-Mg alloys with cooling rate of 20 K/s;

on the tool bar to generate Figure 8 which shows the crack susceptibility map for Al-Cu-Mg alloys with cooling rate of 20 K/s; -

The simulated result is comparable with the experimental results shown in Figure 9.